In manufacturing and construction, 3D printing has emerged as a game-changer. This innovative technology has found its way into various industries, and one such application is in the fabrication of commercial windows and doors. In this post, we will explore the possibilities and limitations of 3D printing in this field.

Understanding 3D Printing Technology

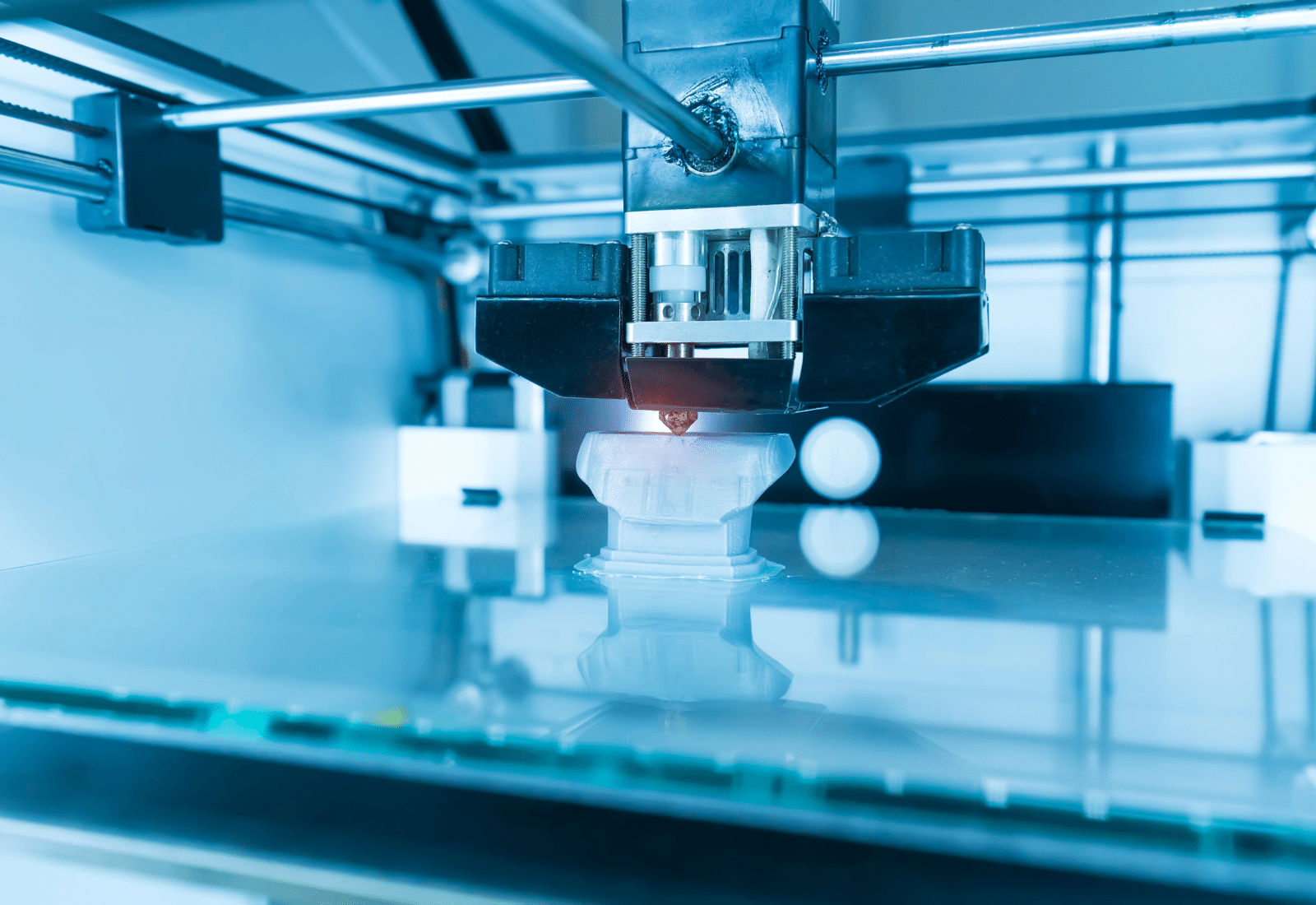

Also known as additive manufacturing, 3D printing involves creating three-dimensional objects by layering material on top of itself, typically in a digital format. This process allows precise and intricate designs to be brought to life with exceptional accuracy. By precisely depositing material layer by layer, printers can produce complex structures that were once challenging or impossible to achieve through traditional manufacturing methods.

This revolutionary technology has applications in various industries, including aerospace, healthcare, automotive, and commercial construction.

Growing Applications in Various Industries

3D printing has seen rapid growth across diverse industries. Its versatility and ability to create complex structures have made it a valuable tool for architects, engineers, and designers alike. From aerospace components with intricate geometries to custom medical implants tailored to individual patients, it has demonstrated its potential to revolutionize how we design and manufacture products.

Advantages of 3D Printing in Commercial Window and Door Fabrication

Design Flexibility and Customization

One of the primary advantages of 3D printing in this context is its unparalleled design flexibility and customization. Designers can create intricate and customized window and door designs that previously were incredibly difficult through traditional manufacturing methods. These designs can be tailored to suit each clients specific needs and aesthetic preferences.

Examples include:

- Intricate Patterns: 3D printing allows for the creation of window and door components with intricate patterns.

- Textured Surfaces: Adding textured surfaces to windows and doors is possible, enhancing their aesthetic appeal and providing a tactile experience.

- Unique Shapes: Designers can explore unique and innovative shapes for windows and doors, pushing the boundaries of architectural design.

- Personalized Designs: 3D printing enables the creation of personalized window and door designs tailored to each clients’ individual preferences, whether they seek a classic or contemporary style.

- Complex Geometry: Complex geometric shapes and forms, such as curves and organic shapes, can be easily realized using this technology.

- Integrated Features: Features like built-in blinds, ventilation mechanisms, or security enhancements can seamlessly integrate into 3D-printed windows and doors.

Rapid Prototyping and Iteration

In commercial construction, time is often of the essence. 3D printing accelerates the prototyping phase, allowing for quick iterations and adjustments to designs. This rapid feedback loop is invaluable in perfecting designs before moving into full-scale production. Designers and architects can swiftly assess the physical prototypes, identify any issues or improvements needed, and make adjustments with ease. This agile approach saves time and minimizes potential errors, ensuring that the final window and door products meet the highest standards of functionality, aesthetics, and performance in a timely manner.

Material Efficiency and Waste Reduction

Additive manufacturing minimizes material wastage, a crucial consideration in today’s environmentally conscious world. By only using the material needed to create the object, 3D printing contributes to more sustainable commercial construction practices.

Environmental Advantages:

- Minimal Material Waste: 3D printing is an additive manufacturing process, which adds material layer by layer to create the final product. This approach minimizes material wastage compared to traditional subtractive manufacturing methods, where excess material is often discarded.

- Optimized Resource Utilization: Materials like polymers, metals, or composites are used more efficiently, as the technology allows precise control over material deposition. This reduces the overall environmental impact associated with material extraction and production.

- Reduced Transportation Emissions: Localized 3D printing facilities can reduce the need for long-distance transportation of pre-fabricated window and door components. This cuts down on fuel consumption and greenhouse gas emissions.

- Recyclable Materials: Many 3D printing materials are recyclable, enabling the reuse of excess or discarded prints, further reducing waste in the manufacturing process.

- Energy Efficiency: Some 3D printing technologies are inherently energy-efficient, especially when compared to the energy-intensive processes often associated with traditional manufacturing techniques.

- Localized Production: By enabling on-site or localized production of window and door components, 3D printing can minimize the environmental impact associated with long-distance shipping and reduce the need for large-scale centralized manufacturing facilities.

Complex Geometries and Functional Integration

3D printing enables the creation of complex shapes and the integration of functional features into windows and doors. This means that these structures can serve more than just aesthetic purposes; they can incorporate advanced functionalities.

For example, windows can be designed with built-in solar shading systems that automatically adjust to maximize energy efficiency. Doors can include intricate locking mechanisms designed for enhanced security. Such innovations not only enhance the overall performance of these architectural elements but also contribute to the overall efficiency and sustainability of commercial buildings.

Limitations of 3D Printing in Commercial Window and Door Fabrication

Size Constraints

While 3D printing is incredibly versatile, it does come with size limitations. Printing large-scale windows and doors can be challenging and may not always be the most efficient method. In such cases, traditional manufacturing methods might still be preferred.

Material Limitations

3D printing offers a range of materials, but not all are suitable for every application. There may be instances where traditional materials are necessary to meet specific performance or safety requirements.

Surface Finish and Quality

Achieving the desired surface finish may require post-processing steps. When compared to the flawless finish often associated with traditional manufacturing, this can be seen as a limitation.

Production Speed

The speed of 3D printing, while impressive for prototyping, may not always meet the demands of fast-track commercial construction projects.

The Future of 3D Printing in Commercial Window and Door Fabrication

Advances in Materials and Technology

The future of 3D printing in this field looks promising. In fact, the industry is estimated to register a CAGR of 21% between 2021 and 2026, and the global market size is projected to grow from $22.40 billion in 2023 to $105.99 billion by 2030. Ongoing developments in materials and printing techniques are likely to overcome current limitations, making it an even more viable option for commercial window and door fabrication.

Integration of IoT and Smart Features

Imagine 3D printed windows and doors with integrated Internet of Things (IoT) devices. Smart windows that adjust transparency based on sunlight or doors equipped with advanced security features could become a reality.

Sustainable Construction

As sustainability becomes increasingly important, 3D printing aligns perfectly with the goals of sustainable construction. Reduced material waste, a smaller carbon footprint, and energy-efficient designs are all benefits that it can offer.

Conclusion

3D printing has created exciting possibilities in the world of commercial window and door fabrication. Its advantages in design flexibility, rapid prototyping, material efficiency, and functional integration are undeniable. However, it’s essential to consider its limitations, such as size constraints, material limitations, surface finish, and production speed.

With ongoing advancements in materials and technology, the integration of smart features, and a focus on sustainability, this technology is poised to revolutionize the window and door industry further. As commercial property owners and developers look to the future of construction, embracing the potential of 3D printing is a step toward more efficient, sustainable, and innovative building practices.

Contact Aeroseal for Your Commercial Window and Door Needs

If you’re interested in exploring 3D printing options for your commercial window and door projects, don’t hesitate to reach out to Aeroseal. Our expertise can help us guide you through the possibilities, helping you make informed decisions for your construction projects.